Model No.︰SLG70-A

Brand Name︰FLD

Country of Origin︰China

Unit Price︰US $ 25000 / pc

Minimum Order︰1 pc

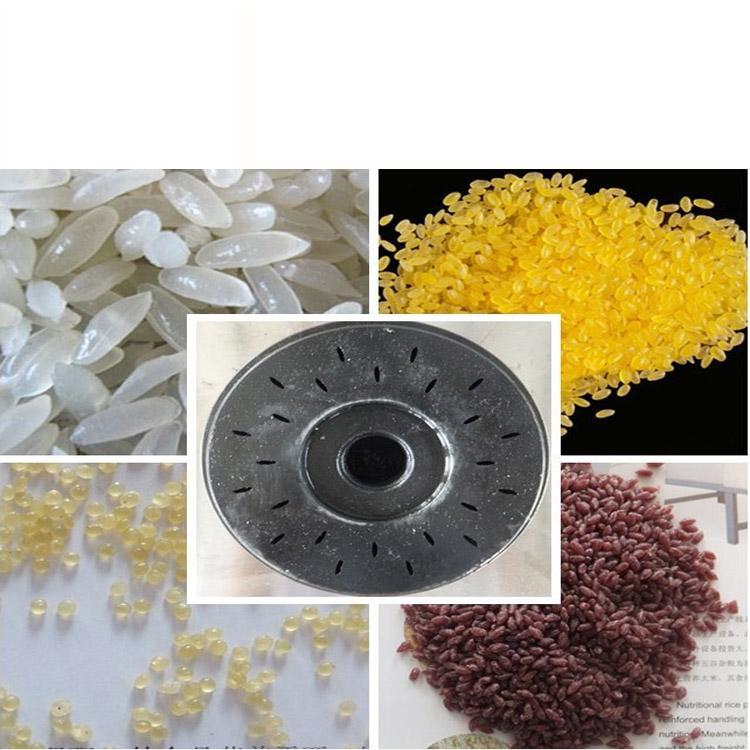

High Quality Industrial Artificial Rice Production Line Artificial Rice Extruder Machine

Product Description

The artificial rice processing machine adopts the broken rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient. The material is extruded into rice shape by the twinscrew extruder, and dried in a rotary dryer to needed moisture content. Artificial rice machine extruding technique makes it possible to strengthen and solidify the micronutrient in the rice. This artificial rice can be mixed with natural rice prior to cooking as usual. When cooking is finished, its grains are not broken and there is no difference between the artificial rice and the natural one in viscosity, elasticity and taste.

Artificial Rice Extruder Machine:

Mixing system---Conveying system----Extrusion system----Air blower----Drying system----Cooling system.

2.Artifical Rice Production Process:

3.The Equipment Parameter Of Artificial Rice Making Extruder:

| Model | Installed power | Actual consumption | Main power | Output | Dimension |

|

DT65 |

34KW | 28KW | 22KW | 100-150kg/h | 2400*1200*1800mm |

| DT70 | 42KW | 30kw | 30kw | 160-200kg/h | 2600*1200*1800mm |

| DT75 | 85kw | 60kw | 55kw | 200-300kg/h | 2600*1200*1900mm |

| DT85 | 92kw | 75kw | 75kw | 300-400kg/h |

4500*1600*2000mm |

| DT90 | 135kw | 91kw | 75kw | 400-600kg/h | 4500*2000*2000mm |

4.Detail Of Artificial Rice Making Extruder :

|

Name: high speed mixer Dimension(m): 1.1×0.8×1.4

|

|

Name: screw conveyor Dimension(m): 3.2×0.6×0.7

|

|

|

Name: Artificial Rice Production Line Artificial Rice Extruder Machine Dimension(m): 2.6×1.0×1.3

|

|

Name: multi-layer dryer Dimension(m): 8.4×1.3×1.8

|

|

Packaging & Shipping

1).Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

2)Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country); by ship-please tell me your delivery port.

Artificial rice making extruder Technical Advantages:

Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished once.The investment for this line is only one tenth of that larger size equipment ,especially suitable to small-size or self-owned enterprise.

Payment Terms︰ 100% TT